※ Microprocessor control system optimizes the welding parameters. Due to the adoption of advanced digital control technology and user

friendly design, all you have to do is select the welding current corresponding to the workpiece thickness to achieve the best weld quality.

※ Automatic mains voltage monitoring.

※ Digital control system offers greater stability of the output power.

※ The welding gun testing function evaluates the usage status of welder more comprehensively.

※ Overheat protection.

※ High precision time and power adjustment system.

※ Complete with triangle washers for dent pulling.

※ Various welding procedures are available such as shrinking, washer welding, dent pulling spot welding, flattening, waveform wire welding,

stud welding, OT washer welding, triangle washer welding etc.

※ Large pulling hammer and waveform wire welding.

※ Stepless current regulation.

Technical Data

Input Voltage:

Input Power:

Input Current:

Max Welding Current:

One-side Welding Thickness:

Packing Dimensions:

Gross Weight:

|

AC 220V or 380V 50/60Hz or 200V/380V

21KVA

55A

5400A

0.8+1.0mm

66×45×43cm (Main Machine)

63.5×45×23 (Trolley)

45kg / 31kg

|

Due to the continuous innovation and upgrade, our products' features may be updated.

Please refer to actual products or contact us for more information.

Details

Accessories

|

Accessories

|

Quantity

|

|

F002 Pulling Hammer with Hook

F003 Dent Pulling Spot Hammer

F006 Wavy Wire

F007 Carbon Rod

F008 Spot Welding Electrode Tip

F009 Carbon Rod Connector

F010 Wavy Wire Electrode Tip

F011 Washer Connector

F013 Triangle Washer Connector

F014 Claw

F015 Triangle Washer

F016 Stud

F017 ɸ12mm Washer

F017 ɸ10mm Washer

F018 Earth Clamp

F019 Manual Cupule

F030 OT Washer

F033 Wrench

F034 Stud Connector

|

1 set

1 set

15pcs

3pcs

1pc

1pc

1pc

1pc

----

1pc

10pcs

30pcs

15pcs

15pcs

1pc

1pc

20pcs

1pc

1pc

|

Pictures for reference only, please subject to our available products.

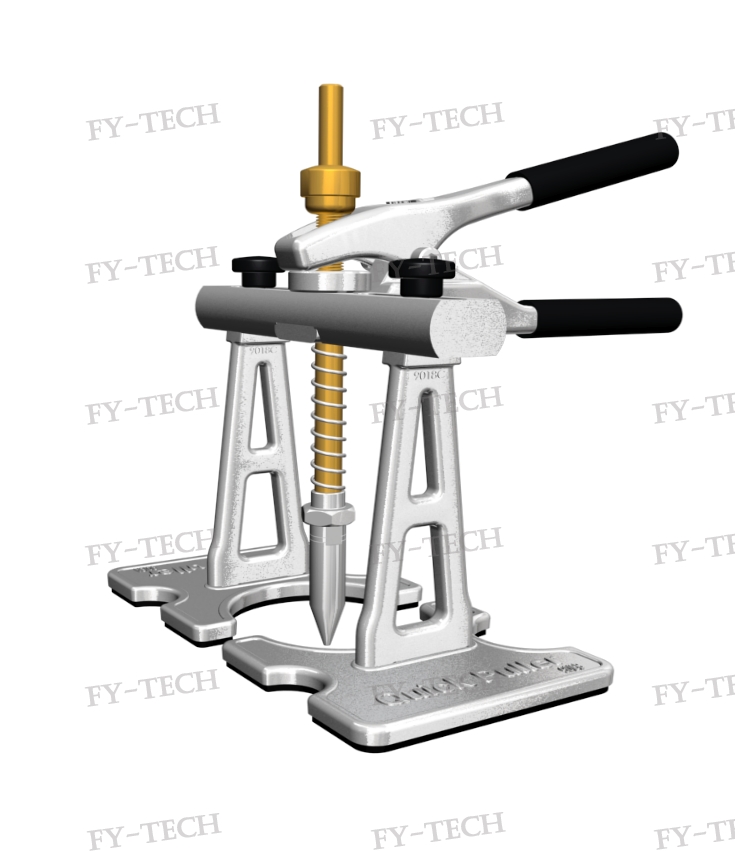

Optional Quick Puller

Pictures for reference only, please subject to our available products.